Product Description

Characteristic Advantages

1. Non blocking structure: The surface of the V-shaped wire gradually narrows to prevent particle blockage;

2. High mechanical strength: The support rod structure is sturdy and can withstand high pressure and mechanical impact;

3. Continuous gap filtration: uniform gap accuracy and excellent fluid permeability;

4. Easy to clean, long lifespan: corrosion-resistant, wear-resistant, suitable for repeated use;

5. Support customization: Size, opening gap, wire width, direction, and material can all be customized

Common Specifications

Available Forms

1. Flat screen panel

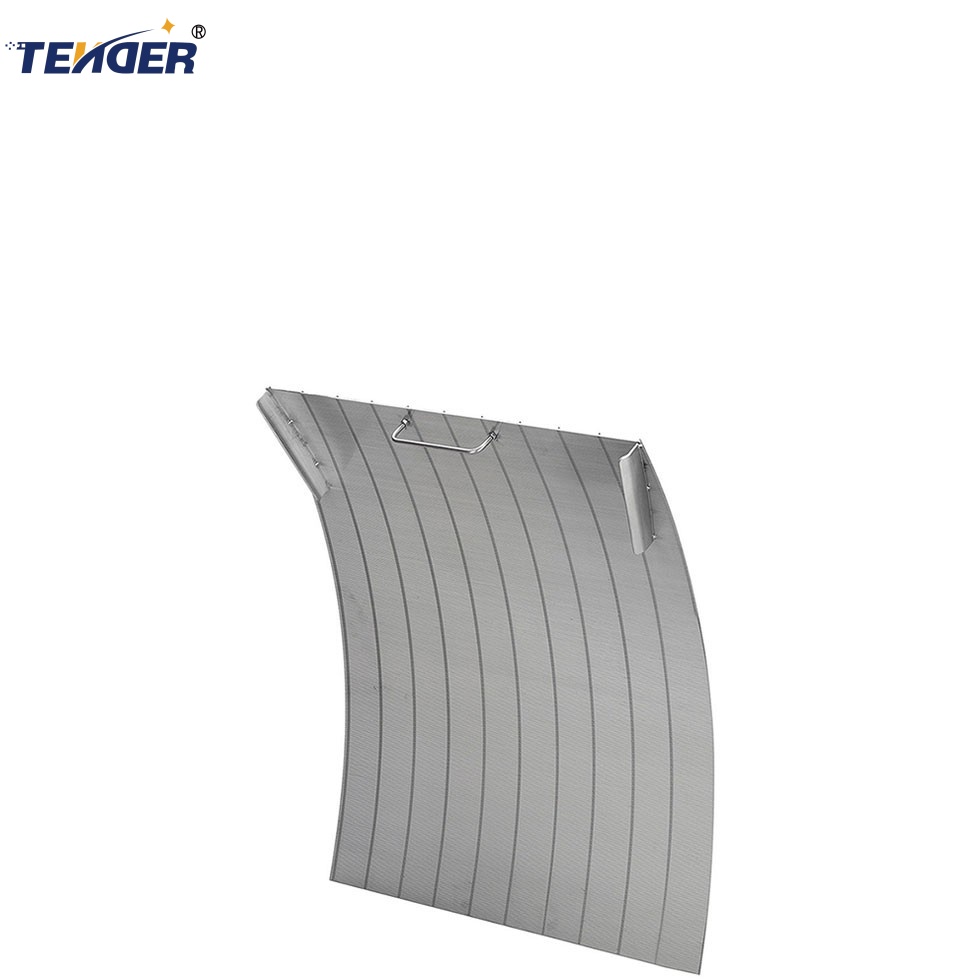

2. Curved wedge wire screen

3. Cylindrical wedge wire screen

4. Conical or basket shape structure

5. Framed&replaceable panels

Parameter | Specification Range / Options |

Material | SS304, SS316L (standard); also: Hastelloy, Monel, Inconel, Titanium |

Panel Size | 300 × 300 mm, 500 × 1000 mm, 1000 × 2000 mm, or customized |

Wedge Wire Shape | V-shaped wire: 0.75 × 1.5 mm, 1 × 2 mm, 1.5 × 2.5 mm, 2 × 3 mm, etc. |

Support Rod Shape | Triangle, rectangular, round, wedge (e.g. 2 × 3 mm, 3 × 5 mm) |

Slot Opening (Gap Size) | 0.05 mm – 10 mm (common: 0.2 mm, 0.3 mm, 0.5 mm, 1.0 mm) |

Open Area Ratio | 10% – 60% (depends on wire size and gap) |

Panel Thickness | 3 mm – 15 mm(depending on structure) |

Flow Direction | In-to-out or out-to-in (customizable) |

Working Temperature | Up to 600°C |

Working Pressure | Up to 5 MPa or more |

Surface Finish | Pickled, polished, passivated |

Mounting Options | Framed, bolted, welded, or removable |

Application Area

1. Water treatment (sewage pre filtration, seawater desalination device, reuse water filtration)

2. Food and beverages (syrup, alcohol, starch dehydration, juice extraction equipment)

3. Petrochemical industry (tower internals filtration, blowout preventer, mud circulation)

4. Mining (coal slurry screening, slurry dewatering)

5. Paper making and fiber separation (pulp screening, filtration)

5. Agricultural irrigation system (drip irrigation filter head)

Our stainless steel wedge wire screen is engineered for high-performance filtration and separation in demanding environments. Designed with a V-shaped profile wire screen structure, it offers excellent mechanical strength, precision filtration, and resistance to clogging. This screen is ideal for industries such as wastewater treatment, mining, food processing, pulp and paper, and petrochemical applications.

Thanks to its self cleaning wedge wire screen design, the continuous slot construction prevents particle buildup, ensuring optimal flow rates and reducing maintenance time. Whether used for solid-liquid separation, dewatering, or drainage systems, the wedge wire design minimizes downtime and increases operational efficiency.

We offer both flat and curved models, including the sieve bend screen, which is commonly used in vibrating or gravity-fed separation equipment. Each screen is customizable in slot size, length, width, and support rod configuration to suit your unique process requirements.

If you're looking for a reliable wedge wire screen for sale, our factory-direct products combine precision engineering with long-term durability. Every screen is corrosion-resistant, easy to clean, and designed for reusability in harsh industrial settings. Upgrade your filtration system with our premium wedge wire solutions for improved productivity and reduced costs.

Our self cleaning wedge wire screen delivers superior performance in continuous flow applications that require high-precision filtration. Made from corrosion-resistant stainless steel, it features a V-shaped profile wire screen that ensures consistent slot openings and excellent debris rejection without clogging.

The unique self-cleaning design reduces maintenance and enhances operational efficiency, especially in systems handling viscous or particle-laden fluids. This type of screen is widely used in food and beverage production, pulp and paper mills, mining slurries, and industrial wastewater systems where downtime must be minimized.

Among our wedge wire products, the sieve bend screen is a top choice for static separation. Its curved surface allows for higher capacity screening with minimal pressure drop. The open area and directional slot design help maintain continuous flow while separating solids from liquids effectively.

We provide wedge wire screen for sale in a variety of dimensions, materials, and configurations to meet both standard and custom industrial needs. Whether flat, cylindrical, or curved, each screen is built with accuracy and durability to withstand high-pressure operations and aggressive cleaning cycles.

Please leave us a message and we will get back to you shortly.